Biomaterials

Joseph A. Spadaro

Michael T. Clarke

Julie M. Hasenwinkel

The advances made in contemporary orthopaedic surgery are intimately related to the development of and use of implant biomaterials. These are materials used to augment, repair, or replace natural tissues or assist in healing. Currently, biological performance is as influential as the mechanical properties of its component materials in the design of an implant. It is now recognized that no implanted biomaterials are actually inert. In fact, instead of demanding inertness, most surgical specialties are embracing “bioactivity” as a means toward a fuller regeneration of the normal state. Orthopaedics is no exception. Only by the orchestration of the mechanical, chemical, and biological behaviors of these biomaterials can further improvements be made.

An understanding of the general principles is therefore crucial to implant selection and expectations on behavior.

Metals and Metallic Alloys

Metals and their alloys of other metallic and nonmetallic elements are used as implants in orthopaedic surgery mainly for bearing and structural components that are typically affixed to bone.

Benefits: bulk biocompatibility, strength, resistance to fatigue failure over millions of cycles

Drawbacks: susceptibility to corrosion, potential for immune stimulation, particulate cytotoxicity and mutagenicity, possibility of fatigue failure in the long term

Implant Manufacture

Raw material is processed in one of three ways (frequently, a combination of two or three is necessary for final implant shape; Table 17-1 gives definitions).

Machining: includes lathing, milling, or grinding of material

Casting: molten alloy is poured into a mold (subsequently broken)

Forging: by bending, compressing, and impacting (often at elevated temperatures)

Final modifications of an implant frequently used are:

Coating (to enhance bone ingrowth or ongrowth)

Plasma spray of powdered hydroxyapatite or metal alloy

Cold deposition of hydroxyapatite

Sintering of beads or wire

Grit blasting (to enhance frictional interference with cement or bone)

Polishing (to enhance appearance, reduce corrosion, and reduce friction on cement)

Shot peening (to enhance fatigue properties of critical areas [e.g., Morse taper junctions])

Alloys in Current Use

Although new alloys are constantly being developed, there are four broad classifications of alloy types currently in common orthopaedic use:

Table 17-1 Some Metallurgical Definitions

Term

Definition

Cold working

The alteration of the shape or size of a metal by plastic deformation. Processes include rolling, drawing, pressing, spinning, extruding, and heading; are carried out below the recrystallization point, usually at room temperature. Hardness and tensile strength are increased with the degree of cold work, while ductility and impact values are lowered.

Hot working

The rolling, forging or extruding of a metal at a temperature above its recrystallization point without significant strain hardening

Warm working

Processing in a range usually 0.3 to 0.6 of melting point

Forging

A process of working metal to a finished shape by hammering or pressing; primarily a “hot” operation. It is applied to the production of shapes either impossible or too costly to make by other methods or needing properties not obtainable by casting. Categories of forgings include hammer, press, drop, or stamping.

Wrought

An alloy that has been significantly “worked” to break down its cast structure

Solution heat treatment

A process in which an alloy or metal is heated to a suitable temperature, is held at that temperature long enough to allow a certain constituent to enter into solid solution, and is then cooled rapidly to hold that constituent in solution. Most solution heat treatments soften or anneal.

Annealing

A heat treatment that relieves internal stress. Solution-annealed material is frequently in its most corrosion-resistant and ductile condition.

Work hardening

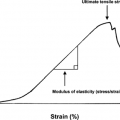

A term that signifies crystalline changes when a material is strained beyond its yield point

Grain boundary

As metals solidify (crystallize), many individual regions (grains) form with differing orientations of the atomic lattice. The region where grains meet (boundary) is less dense and more chemically reactive than the bulk material.

Passivation

A process of formation of an oxide layer on the surface of an alloy or metal. This can be spontaneous in the environment or enhanced chemically, for example by immersion in nitric acid. Passivation generally leads to improved corrosion resistance.

Titanium alloys

Cobalt chromium alloys

Stainless steel alloys

Tantalum-carbon

Titanium and its Alloys

Although developed as an aerospace alloy, titanium is well known in the medical field for its biocompatibility and high strength-to-weight ratio.

It is broadly used in the manufacture of fracture and spinal fixation devices as well as nonarticulating joint replacement components.

Orthopaedic Uses of Titanium Alloy

Fracture and spinal fixation devices: screws, plates, in-tramedullary nails

Joint replacement components

Cementless total hip: acetabular shells, femoral stems, ingrowth or ongrowth coatings

Not femoral heads (historically abandoned due to high wear)

Total knee: tibial tray, ingrowth or ongrowth coatings

Not femoral bearing surfaces (historically abandoned due to high wear)

Metallurgy

Titanium is typically alloyed with other elements as well as being thermomechanically treated to achieve the desired properties for implantation.

Metallic alloying increases the strength and maintains ductility by replacing titanium atoms in the crystal lattice with other metal atoms such as aluminum, vanadium, zirconium, and niobium.

Nonmetallic interstitial elements such as oxygen, carbon, and nitrogen lie in voids between atoms of titanium.

Strength is gained, but ductility and toughness are reduced.

The natural crystal state for pure titanium (CPTi) is an alpha phase with a hexagonal close packed (hcp) crystal lattice.

An alternate beta, body centered cubic (bcc) crystal phase is present in varying extents in titanium alloys depending on the alloy and heat treatments performed.

Beta-phase alloys can be harder and more brittle than alpha-phase ones.

In the commonly used titanium—aluminum—vanadium, an alpha-beta alloy, aluminum stabilizes the alpha phase and vanadium the beta phase.

The newer substantially beta-phase alloys containing molybdenum impart superior strength to an alloy and have the lowest elastic modulus (80 MPa) of any of the commonly used bulk implant alloys (e.g., CoCrMo 200 MPa).

Box 17-1 General Advantages and Disadvantages of Titanium Alloys

Advantages

Excellent biocompatibility

Relatively low elastic modulus

Spot welding to itself in taper junctions

Low galvanic corrosion to CoCrMo alloy

Disadvantages

Poor wear properties Notch sensitive

Concern with vanadium and aluminum content in specific alloys

Titanium Implant Characteristics (Box 17-1 and Table 17-2)

Advantages

Biocompatibility: result of a highly inert, insoluble, and adherent 10-nm-thick surface passivation layer of titanium oxide (titania, TiO2), allowing superior corrosion resistance

Inert passivation layer of TiO2 significantly reduces galvanic corrosion to cobalt base alloys at taper junctions (e.g., femoral head/femoral stem of total hip replacement [THR]).

Low elastic modulus (80 to 110 Mpa)

Useful in the prevention of stress shielding around cementless implants such as femoral hip replacement stems, but is to be avoided when used with polymethylmethacrylate (PMMA) cement as it is prone to increased cement stresses from bending as well as abrasive wear against cement due to poor wear properties

Spot welding at titanium-titanium taper junctions (e.g., stems on tibial base-plate for total knee replacement [TKR]) minimizes micromotion and fretting.

Disadvantages

Poor wear properties: resulted in general abandonment of titanium alloys as wear surfaces except for custom implants (e.g., in nickel-sensitive patients where cobalt alloy or stainless steel are to be avoided)

For custom titanium bearing surfaces, surface hardening is performed (e.g., ion implantation or nitriding)

Even the nitrided surface may be subject to delamination.

Notch sensitivity: problem for all alloys, but particularly so for titanium

Sharp angles, scratches, and sintered powder or beads allow stress risers to concentrate in one area, significantly reducing the fatigue life of an implant.

Vanadium, and to a lesser extent aluminum, are considered undesirable elements due to cell cytotoxicity seen in vitro and theoretical concerns about biocompatibility. Newer, currently unproven alloys that omit one or both of these alloys have been developed to avoid these theoretical concerns.

Cobalt-Based Alloys

Cobalt-based alloys, most notably of the cobalt-chromium binary system, are widely used for load bearing as a result of their fatigue resistance, and for wear surfaces as a result of their exceptional hardness when properly formed. Many of the properties of the alloys arise from the following:

Table 17-2 Different Uses of Some Titanium Alloys | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||||||

Box 17-2 General Advantages And Disadvantages of Cobalt-Based Alloys

Advantages

Good biocompatibility Fatigue-resistant Wear-resistant

Low galvanic corrosion to titanium

Disadvantages

Galvanic corrosion to stainless steel

Concerns regarding nickel content

Cobalt and chromium ion release

High elastic modulus

Expensive

Difficult to process

Crystal structure of cobalt

Strengthening effects of chromium, nickel, tungsten, and molybdenum

Formation of hard metal carbides (e.g., chromium carbide)

Corrosion resistance imparted by chromium, nickel, and molybdenum alloying elements

Orthopaedic Uses of Cobalt Alloys

Fracture and spinal fixation devices: braided wire for fracture fixation

Joint replacement components

Femoral heads for metal-on-plastic and metal-on-metal bearings

Femoral stems for cemented and cementless THR

Femoral component for TKR

Ingrowth or ongrowth coatings on implants (e.g., THR/TKR)

Metallurgy

Cobalt alloy in cast or wrought forms is typically alloyed with varying amounts of chromium and molybdenum.

Tungsten and nickel are used in some alloys to achieve the desirable properties of strength, fatigue resistance, and corrosion resistance.

Mechanical properties of cast alloys can be improved by hot forging that removes pores and reduces grain size.

In some alloys (e.g., MP35N), cold working can change the crystal structure from a face centered cubic (fcc) lattice to an hcp one, creating a biphasic alloy that has improved resistance to plastic deformation and increased strength.

The presence of carbon is carefully controlled as this can affect the mechanical properties, including toughness, wear resistance, and corrodibility.

High carbon (>0.14% w/w) alloy is used as bearing surfaces against itself.

Low carbon (<0.14% w/w) alloy is used as structural members as well as for coating applications in addition to bearing applications against the ultra-high-molecular-weight form of poly(ethylene) (UH-MWPE).

Cast alloy may be porous, and mechanical properties are improved by hot forging or hot isostatic pressing (HIP) that removes pores and reduces grain size.

HIP is a process of heat treatment in argon gas at high temperature (e.g., 1200°C) and pressure (e.g., 1000 Atmospheres), followed typically by solution annealing.

Advantages

Biocompatibility

Provided by a chromium oxide passivation layer that may be enhanced prior to implantation by cleaning, polishing, and an oxidizing nitric acid bath (see Table 17-1)

The solubility in water, however, is greater than TiO2 and there is susceptibility to crevice corrosion, with concern about possible loss of implant fixation in the long term when directly apposed to bone.

Improved fatigue resistance

THR stem fractures with cast stems: a concern in the past

Better metallurgical processing of alloys and improved alloy compositions have essentially eliminated this as a problem, to the point where wrought cobalt alloys provide some of the most fatigue-resistant alloys available for implantation.

Wear resistance

Table 17-3 Different Uses of Some Cobalt Alloys

Material

Crystal Structure

Uses

Notes

Cast cobalt-chromium-molybdenum alloy (ASTM F75)

fcc

Femoral heads, metal-on-metal bearings, femoral component of TKR

Comes in high- or low-carbon versions. Can be heat treated (hipped, solution annealed). Low nickel content.

Wrought cobalt-chromium-molybdenum alloy (F799, F1537)

fcc

Cemented femoral stems, metal-on-metal bearings

Wrought version of cast F75. Comes in high- and low-carbon versions. Low nickel content.

Wrought cobalt-chromium-nickel-molybdenum

fcc and hep

Femoral stems

Extremely strong; fatigue and corrosion resistant. High nickel content has caused limited use in vivo.

Table 17-4 Mechanical Properties of Some Implant Alloys

Alloy

Yield Strength (Mpa)

Ultimate Tensile Strength (MPa)

Fatigue Strength (Mpa)

Elastic Modulus (Mpa)

Titanium Alloys

Alpha-phase commercially pure titanium

Grade 1 (0.18% oxygen)

172

241

—

110

CpTi (ASTM F67 by ATI Allvac)

Grade 4 (0.4% oxygen)

480

550

380

110

Alpha-beta-phase titanium-aluminum-vanadium (ASTM F136 by ATI Allvac)

793

862

600

110

Beta-phase titanium-molybdenum-zirconium-iron alloy (ASTM F1813 by ATI Allvac)

965

1000

—

80

Cobalt Alloys

Cast cobalt-chromium-molybdenum alloy (ASTM F75)

As cast

450-520

655-890

207-310

210

HIPped

841

1277

725-950

253

Wrought cobalt-chromium-nickel alloy (ASTM F562 by Carpenter-MP35N)

Annealed

414

931

—

232

55% cold-worked

1413

1827

—

232

53% cold-worked and aged

1999

2068

793 max

232

Wrought cobalt-chromium-molybdenum alloy (ASTM F799/F1537 by Carpenter-BioDur CCM plus)

Annealed

882

1351

—

—

Hot-worked

930

1365

900 max

210

Stainless Steels

Nitrogen-strengthened stainless steel (ASTM F1586 by Sandvik-Bioline Hign N)

Annealed

430

740

—

—

Cold-worked

1100

1350

—

—

AISI 316L stainless steel (ASTM F138 by Sandvik-Bioline 316LVM)

Annealed

190

490

270

200

Cold-worked

800

1100

300

200

Nickel-free stainless steel (ASTM F2229 by Carpenter-Biodur 108)

Annealed bar and wire

607

931

381

40% cold-worked bar and wire

1551

1731

80% cold-worked (wire only)

1862

2206

Forged material water quenched for hip implants

1036

1253

513

Tantalum

Pure Ta (ASTM 560-04)

Solid material

345

186

Ta-C

75% porous components

63

3

The numbers shown are frequently greater than the ASTM minimum specifications.

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree